Turn On The Lights!

A long time ago somebody I've known made an analogy about being a motorcycle mechanic;

It's like being in a huge warehouse with no windows.

With experience, you find a book of matches. When you strike one, you begin to understand the scope of the undertaking.

However, you soon realize that the match is a low intensity, short duration, source of illumination.

When you first use a dynamometer it's like the Zep sale representative has just given you the free penlight.

But, when you are introduced to the capability to view the air/fuel ratio in association with engine speed and load, you are standing in front of the main switch panel.

How can somebody stand in front of the switches and not turn the lights on?

How, indeed. The first thing you need to do to make yourself flip that switch is to believe.

Believe that there are benefits to be had from checking and adjusting the air/fuel ratio and ignition timing.

Believe that you might not be getting perfect results 'seat-of-the-pants'.

Where have I heard the saying; 'if you don't check your work, you can assume it's perfect'?

I believe because I see the results every time I tune a bike.

First, I'll show that a proper air/fuel ratio will produce the maximum power.

Second, I'll demonstrate that there are some stock bikes that aren't air/fuel optimized.

Third, I'll pose some questions/comments about the state of fuel injection in the motorcycle industry.

First;

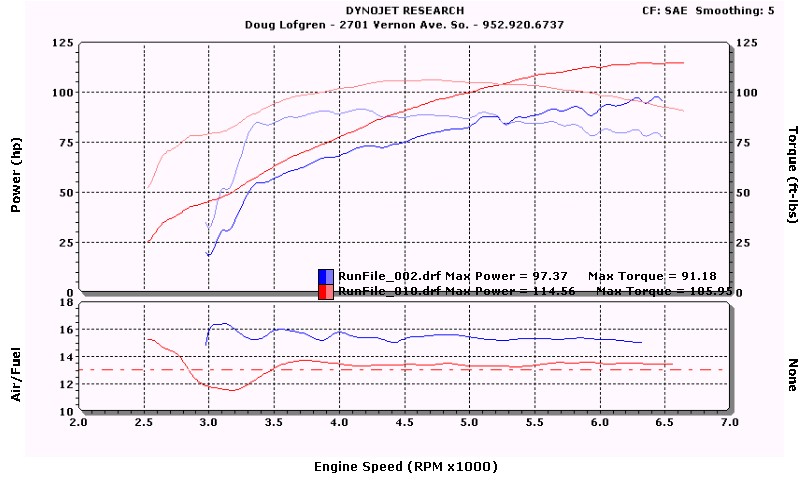

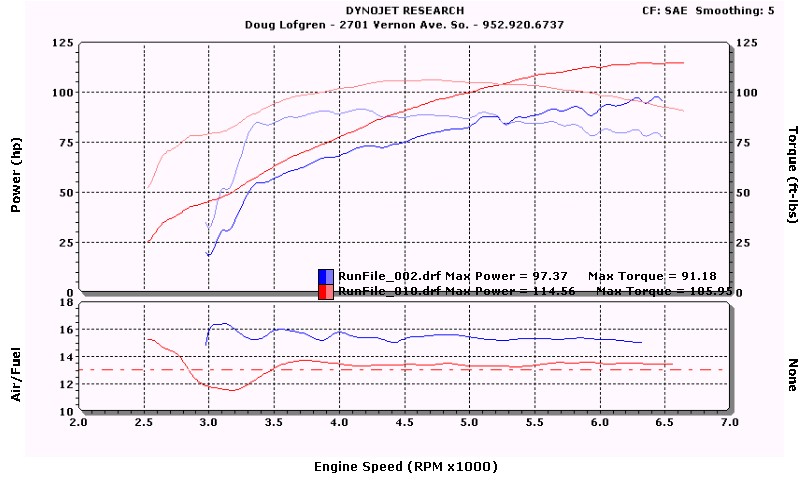

Here is our 2003 H-D Dyna Wide-Glide with billet heads, 0.625" lift cam and a modified S&S 'G' carb. This is the start of our testing, so we started with no idea what jets to use. Run #002 (blue) is really lean with a 15.5:1 air/fuel ratio and several jet changes later you can see the smoothness of the power and torque curves as well as the increases.

And another example;

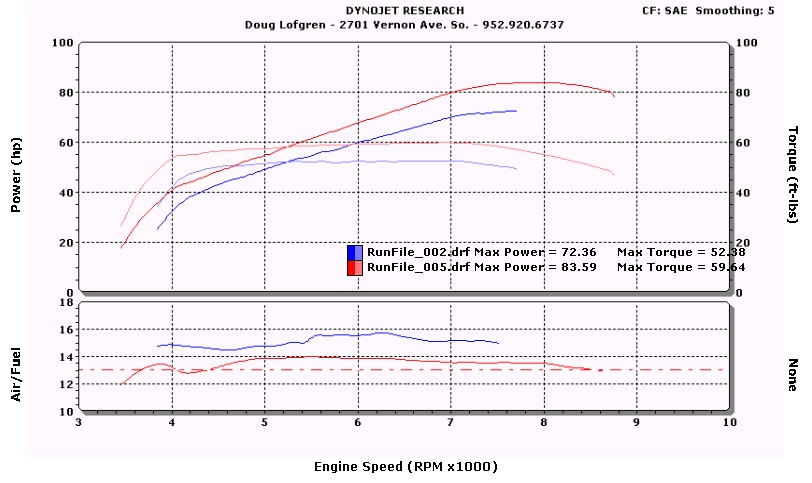

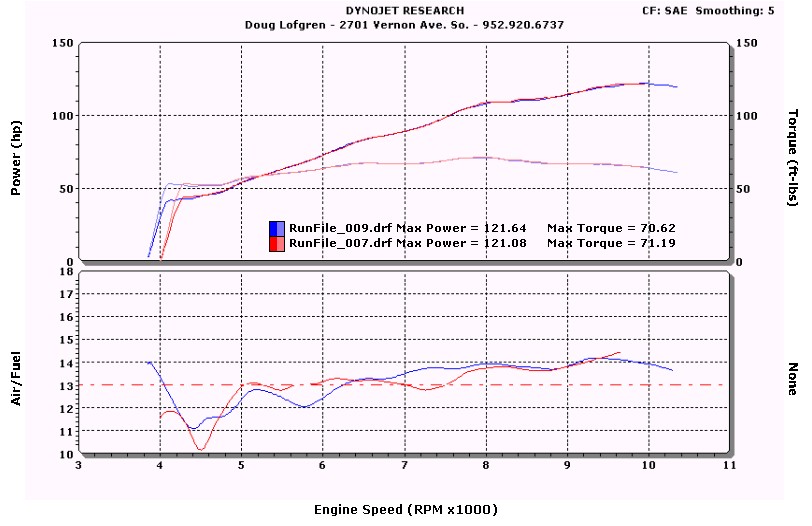

This is a Ducati ST2 with the stock chip (run_002, blue) and the next test with a chip that I had done for another bike. Note that the A/F ratio started out between 14.5:1 and 16:1 and when it got richer than 14:1 a lot of power was available.

After the initial runs with the stock chip I checked the files using the FIM software to be sure that the injector time of the chip that I was considering was greater, and the result is above.

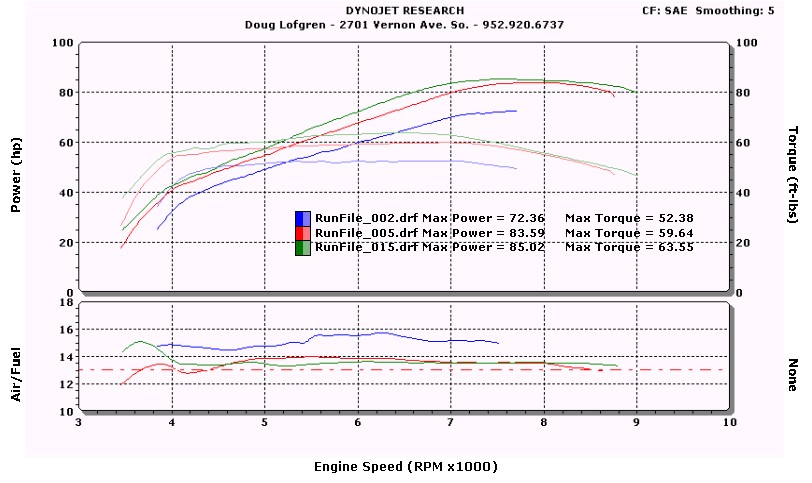

The chart above isn't the final test, just the first two iterations. I didn't stop there and the final result is below.

The A/F ratio improvements aren't the entire deal, ignition timing plays a part in it too. Clearly, the engine likes what I've done.

I've shown that a proper air/fuel ratio will produce the maximum power.

Had enough?

OK, once you've seen the improvement several thousand times and believe that the A/F ratio numbers are telling you the truth, you begin to see the value of these tools.

I'll trust that I've made that point.

Next, Cylinder to Cylinder Variation

The previous charts show the average A/F ratio from both cylinders because both of the exhaust systems in previous examples have a 2 into 1 junction.

With the exception of the Sagem system on the Triumphs (and I just don't know about them), all of the current fuel injection systems have some means of mapping a second, or second pair of, cylinder(s.)

Even though you can have an engine with all cylinders being essentially identical, exhaust systems can cause different mapping requirements for each.

Instead of assuming that both cylinders are the same and have perfect mapping for each, then settling for a good average, I was forced to take a look while mapping an MH900e.

This particular bike had a 2 into 2 separate exhaust system and I had been trying to adjust the main (both cylinders) map while checking the A/F from right side pipe. With most Ducatis, that would get an average A/F ratio for both cylinders. Once I figured out that I'm an idiot, it became evident that I had been checking the rear cylinder pipe and changing both cylinders. When I checked the front cylinder the reason for my rearward progress became apparent.

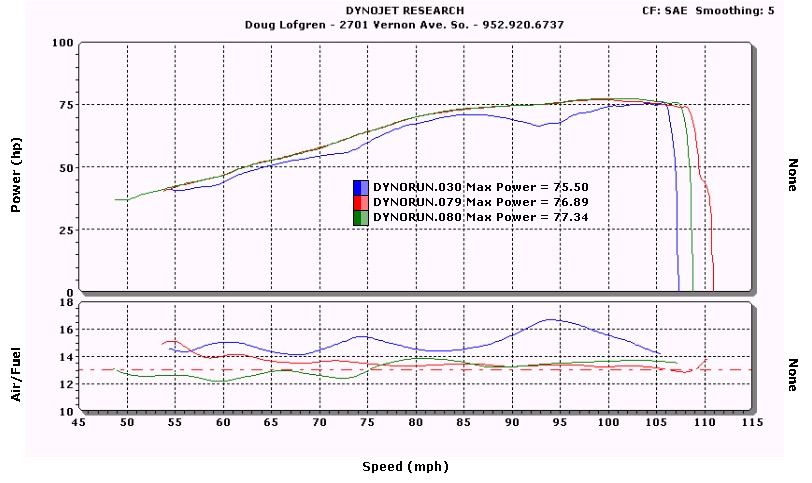

Run 029 (blue) is the rear cylinder (that looks OK, just a little rich) but run 030 (red) is the front cylinder and it is clearly wayyy too lean. I had been trying to lean out the rear cylinder with the main map without checking the A/F on the front. The front became lean enough to misfire, creating the dip at 93MPH.

This graph is shown with MPH on the X axis because the tach pick-up was having troubles and the chart is intermittent if I use RPM.

Then I started to get it right.

As you can see, when I finally got a flat (or flattish) A/F trace on both cylinders (red, 079, front and green, 080, rear) the power was much better everywhere.

The rest of the mapping, such as the part throttle stuff, showed similar improvements.

Another thing to notice with this example, is that the peak power numbers aren't very much better but, which do you think would be a better accelerating bike?

Maybe it was just the pipes that created that inconsistency.

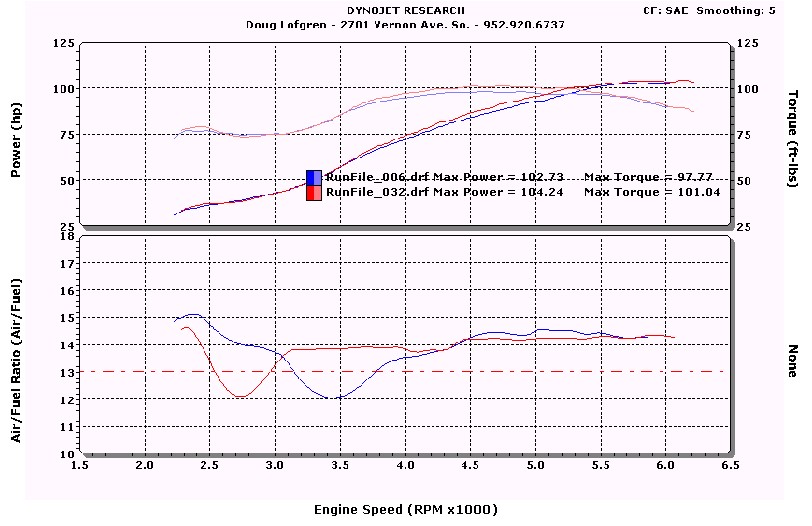

Below I've shown the A/F of both cylinders of a Twin Cam H-D starting with a good map from another bike.

This chart shows the starting A/F ratio for front (blue) and rear (red) cylinders. The starting map had been created for another bike which had lower peak power and a different exhaust system. Below is graph of both bikes, both cylinders, same map.

You might ask why there is a variation in power and torque for these two runs. That is because I adjusted the A/F ratio on the front cylinder between runs 6 and 32, so the front cylinder was contributing more power and torque by the time I started working on the rear. Since I didn't change the rear cylinder map, the rear cylinder was working just like this until I began to change it.

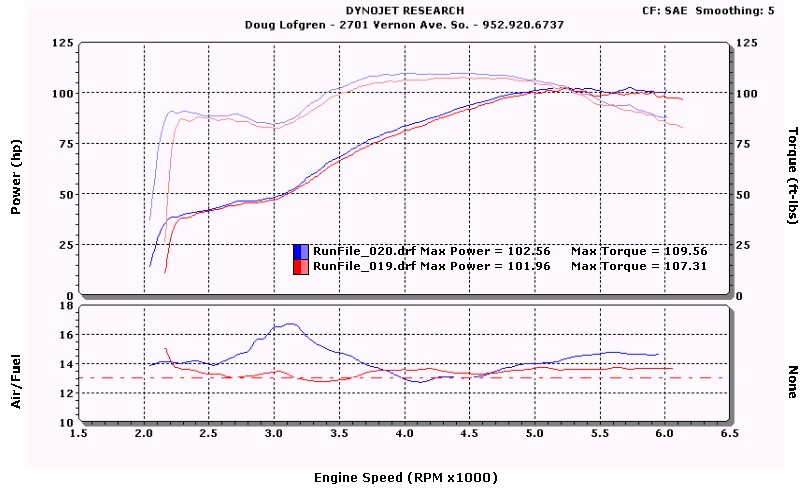

And, one more example of cylinder to cylinder variation on a Harley.

This particular example is a Delphi injected bike with a Thunder Header and a Dynojet PCIII USB. The front cylinder A/F trace is in red, as you can see it's pretty good. When I put the A/F sensor probe in the rear cylinder, I got the blue trace.

This bike had been done with a very rich map and it actually didn't demonstrate the lean condition (on the rear cylinder) at 3000 RPM/WOT that it did after I leaned it out. It did, however run like crap everywhere else.

That's pretty strong evidence for mapping the cylinders seperately.

Second;

No doubt, stock bikes are much better.

Or are they?

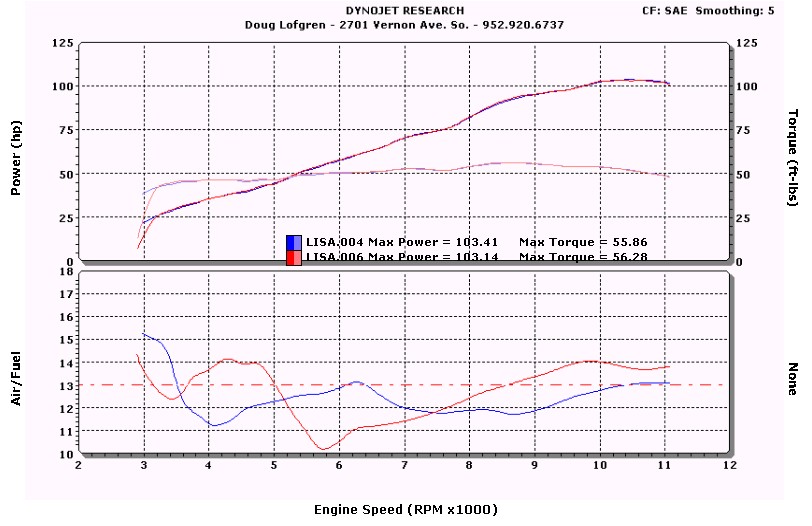

Brad Black sent a Dyno chart of two cylinder A/F traces from a 749S with a DP performance kit with the DP ECU. One cylinder swings from13.1:1 to 11.2:1, while the other varies between 14.2:1 and 10.2:1.

There is lots of torque to be gained at 6000 RPM all the way up to 10,000 RPM, which is the only place that the A/F ratio is even close to balanced.

Here is a chart of a new 999 that was being broken-in on Manley Cycles dyno. Tom Manley decided to check the A/F ratio on both cylinders.

The front cylinder is the red trace and the rear is the blue. Both need to be adjusted for transients at the low end of the WOT graph (4000-4500 RPM), and they both start a little too rich and end up too lean. Along the way the A/F ratios diverge from one to the other. The front cylinder appear to be going lean enough to loose power at the very top while the rear is coming back to a good A/F ratio.

Tom says that the part throttle stuff is worse than these examples, and that concerns drivability.

Third;

Do I expect you to believe that 'the factory' doesn't do a better job than that?

Frankly, I'm surprised the situation isn't any better than that, too, but I've seen the results using the equipment that works for everything else I do. What else am I to believe?

I've heard it said before that the manufacturer has entirely different requirements than the customer.

The manufacturers need to pass stringent emissions tests which have little or nothing to do with WOT power. The road part of the emissions certification process deals with acceleration rates that any car can achieve, how far up the map do you think that goes on your GSXR1000?

The process is so expensive that I can believe that they stop mapping when they get a 'certification'. Once a manufacturer gets the green light to start selling bikes, they do. Time to re-coup the 10s of thousands of Dollars or millions of Lira that they've spent getting that far.

In addition, something as simple as the slip of a key-stroke can cause a different map to be installed on all the OEM ECUs.

There's one more element to this thing. There are wide variations in fuel pressure from one bike to the other. Harley-Davidsons specification for fuel pressure is 4 bar + or - .25 bar. That represents a 13.33% variation in pressure which is a 6.46% variation in fuel flow.

The manufacturer may not even understand the implications of this fact on performance across any product line, but they can't afford and/or don't want to find that out. Even if the manufacturer would care about that, they have little technical staff at the distributor level to monitor/detect that.

Yeah, I believe it!

Why wouldn't someone 'turn on the lights'?

My exposure to lots of people in the motorcycle industry has lead me to believe that we all do the work we do with the tools we have.

What that means is, we acquire the minimum tools we need and then work with those tools.

Harley guys need a boring bar and hone to build engines. Ducati guys don't need a boring bar or a honing machine.

If a mechanic has enough tools to do the work he's known for and makes his customers happy, why should he spend any more $$?

The Dealerships

I went off on my rant about tuning fuel injected bikes to a friend who works at the local Ducati dealership. His response was 'the customers won't know' if they're tuned properly.

That's true for all of his customers, but since they don't have the capabilities, the customers that do know that they need better tuning, won't go there. There is no reason a dealer shouldn't be able to offer all of the customers all of the capabilities, especially when some of the brands are offering performance.

Profitability in performance work/tuning can be elusive, but in a big dealership, there is prestige in being able to solve all of their customers problems, to say nothing of the value they offer to the distributor. These are two things that may be difficult to put a dollar value on, but a competent reputation definitely has a value.

I talked to a long time friend who has worked at Harley dealership since our Vo-tech days together. The dealership has a dyno and advertises that they are the fuel injection experts. They have even had fuel injection training by MMG Management.

John says that he can't spend the time to map bikes like I do. The problem is that he is a commission mechanic and nobody at the shop has bothered to change the way they sell fuel injection mapping services. The service writers don't know anything about the results and the mechanics haven't ever spent the time to find out just how remarkable the results can be.

Nobody at the dealership has thought that it might be doing the customer a favor to be able to offer them a higher quality motorcycling experience.

As with everything else it takes training to change this situation. Training the customers and training the service providers.

I've sent my resume to Pro Italia, Ducati Milwaukee, and Moto Primo and they all worried about hiring somebody with my experience level because of how much it might cost to employ me. They fail to see the value in complete fuel injection competency.

Don't believe in dynos or fuel injection mapping

I run into a few folks who claim they don't believe in dynos or that fuel injection mapping. There are probably more than a few, but they won't say that to my face. There's nothing wrong with avoiding confrontation, but sticking your head in the sand is kinda' shameful.

Everyone is entitled to their opinion, but I think everyone owes it to themselves to get some facts before rejecting a concept.

From 2 decades of dynamometer use and thousands upon thousands of dyno runs, I have lots of results to influence my opinion on the subject.

People who claim that a dynamometer isn't a good tool are usually making excuses for not having a dyno. Based on no data.

That's like stating that a torque wrench doesn't work, because you've never used one. I'm sure there are people who claim that too.

The guy who told me that he hopped up an injected Triumph and messed with it for a year without getting it to run right, is the same guy who claims that fuel injection mapping is just 'smoke and mirrors'.

And, More on the Subject of Dynos and Performance

Mike Summers E-mailed me with this;

Doug, I just read your "Turn the lights

on" article, very interesting!

There is one dealer that figured out that "Dyno

Tuning" is good for business, it was an auto dealership in Chicago and the

year was 1963... Grand Spaulding Dodge.

I'm not sure if you know the history but a fella known as "Mr Norm" Sold not just fast cars to customers, but a total performance package, INCLUDING CHASSIS DYNO tuning. This business practice elevated Grand Spaulding dodge to be the largest Dodge dealership in the world along with the largest parts and service departments dedicated to high performance in the country.

The story I've heard is something like this... After they sold the customer a new car the customer would be offered a free dyno run and the car would put out somewhat mediocre HP numbers. The salesman would offer some performance tuning and hop up parts and include it in the financed amount for the new car. When the customer came back to pick up the car, it would go back on the chassis dyno for a final run, the customer could see with his own eyes what the improvements were. As a result the customer spent a bunch of money at the dealership and drove away very happy. Apparently this died with the muscle car and never resurfaced.

I think there are many parallels between the Muscle car era and the modern sport bike popularity. Why a large metropolitan dealership wouldn't want to explore the same possibilities is beyond me?

Cheers

Mike Summers

I had a conversation with Jason Etter of Section 8 Superbikes in Michigan. I mentioned that I thought fuel injection calibration software was an important part of making and selling performance.

Jason mentioned the success of the 5.0 liter Ford engine. He feels that the success of that engine in the performance world is due to the availability of fuel injection mapping capabilities.

Conclusions?

The motorcycle industry (with the possible exception of H-D) hasn't begun to understand the full potential of fuel injection mapping capabilities.

They understand that the performance market taps into enthusiasm for the brand.

They don't understand the part it plays in selling performance and the overall competence that comes from the use of those capabilities.

The dealers who have that competence are too few and far between. Those few have the loyalty of their customers.

Performance enthusiasts should demand that kind of competence from their dealers.